The artifact illustrated on the 2019 Arkansas Archeology Month poster, and in this essay, is a Means Engraved bird effigy bowl in the University of Arkansas Museum Collection, made some time between AD 1300 and 1600. It was retrieved during 1930s WPA excavations at the Adair site in the upper Ouachita River Valley. Explore the model below to take a closer look.

3D CONTROLS - Use your mouse to rotate the object. Use your scroll-wheel to zoom in or out.

Model created using the Artec Space Spider 3D scanner. This model and all other images on this page are copyrighted ©Arkansas Archeological Survey. Do not reproduce without permission.

By Teka McGlothlin and Sarah Shepard

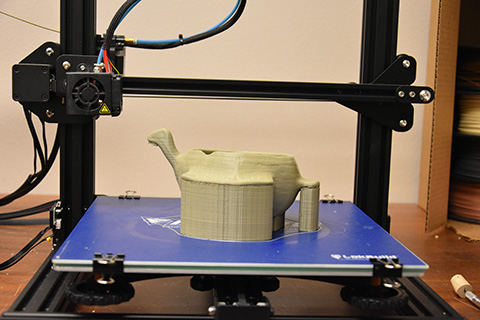

In 2018, the Arkansas Archeological Survey purchased a hand-held Artec Space Spider 3D scanner with the goal of being able to scan artifacts and make them more accessible to the public through an online web presence. The scans offer various ranges of potential research, including the ability of researchers to view certain items without requiring the artifact to be pulled from curation. Later in 2018, the Survey was able to purchase a 3D printer through a grant from the Arkansas Natural and Cultural Resources Council. The printing surface has the capacity to produce models up to twelve by twelve inches in diameter. These productions can be used for displays in public spaces without the risk of harming the actual artifact. Additionally, these models aid in educational outreach exercises by allowing students to handle items that might otherwise be too fragile.

The process begins by placing the artifact on a rotating table, allowing for smooth surface coverage. The scanner records seven frames per second using structured blue light technology. This ability permits us to scan artifacts in a well-lit area by filtering out other light sources, which increases the scanner’s portability. The images are processed through Artec Studio, using a workflow co-developed with the Center for Advanced Spatial Technology at the University of Arkansas. Among other things, actions within the workflow help to filter out background noise or smaller objects that might have been picked up in the scanning process. We are also able to adjust texture by using alterations in brightness, hue, and contrast in order to reflect the artifact’s appearance. Once this process has been completed in Artec, the image is now ready to be digitally curated.